• Mine equipment performance analysis and benchmarking

• Equipment selection and bid strategy

• Mine equipment stability, rolling resistance and emissions reduction– leading to road design strategies

• Pad and running surface ground performance evaluations

• Operations troubleshooting and remediation

• Mine waste and tailings management

• Conventional truck-shovel, IPCC and dragline mine planning

• Hybrid and new concept mine methods, design and planning

Geo-mechanical testing and analysis training

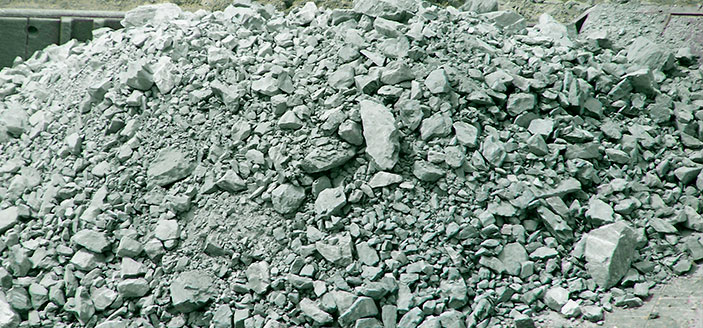

• Full intact rock core, block and broken chip testing services

• Triaxial and uniaxial compressive strength tests

• Brazilian tensile and compressive strength tests

• Point load index parallel and perpendicular to core tests

• NCB cone indentor compressive strength index tests

• Shore schleroscope compressive strength and Vickers hardness

• Slake durability and JPi`s modified G65 tire – rock durability tests

Ground – equipment interactions testing & analysis training

• Rolling resistance testing and analysis services

• Cyclic unload – reload track or tire – ground performance tests

• Tire performance (tkph) analysis

• CBR/resilient modulus road material performance tests

• Swell factor verification and variance analysis

• Wear protection choice – wear abrasion performance tests

• Bucket fill factor evaluation tests

Contact Us

JPI mine equipment is based out of St. Albert, Canada. Contact us to discover what short courses we can offer you today; to allow you to make more informed, immediate and significant cost-effective, sustainable and operational changes.

admin@jpicanada.com