Mining 20:20 – a 101 perspective

2 Day Courses

An overview of global mining operations, from exploration through designing for closure to operation, processing and handling mine waste. Safety issues, operational roles and relationships with the community are highlighted.

Course Content• Safety first

• Global mining opportunities

• Rocks & minerals – what is ore?

• Exploration & size of deposits

• Resources & reserves & cost to mine

• Open pit mining concept to closure

• Underground mining concept to closure

• Volume, stripping ratio, swell factor from bank to plant

• Processing and tailings

• Mining towards closure

• Who does what in a mine?

• What are the rules we must mine by?

Mining methods, modes & machines

4 x 1 Day Courses

Four, 1 day courses are offered introducing mining equipment, mining methods and alternative modes of operation. Hybrid mining techniques are explored to enhance availability and productivity with minimal environmental impact

Truck-shovel, IPCC, dozer and hybrid operations• Haulage and loading by shovel, excavator and FEL

• Dozer trapping to shovel, FEL or hoppers

• Excavator – IPCC operations

Dragline operations

• Opening cuts & Simple side casting

• Advanced and Extended bench mining

• Dualing draglines

• Dragline – hopper – truck loading

• Highwall mining and hybrid operations

BWE and continuous mining operations.

• BWE & conveyor operations

• Surface miner operations

Underground mining, tools and techniques

• Stoping and caving operations

• Room and pillar operations

• Longwall operations

Mineral processing, mine waste & operations

2 Day Courses

An overview of mineral processing techniques, with a focus on achieving a low total energy balance between crushing & grinding, mine excavation and blasting, lessening impacts on mining and processing equipment. Mine waste from rock dumps to tailings, and achieving stable reclaimable and trafficable surfaces is investigated.

Course Content• Comminution (crushing & grinding systems)

• Minimizing Energy between blast, excavator and crusher

• Screens and Cyclone sizing

• Hydrometallurgy – floatation, ion exchange and crystallization

• Oil sands processing case study

• Processing waste streams and tailings strategies

• Thickened and dried tailings

• Tailings failure modes and case studies

• Gold processing and cyanide treatment

• Pyrometallurgy issues

Beyond the stopwatch (truck – shovel operations)

2 Day Courses

Using your existing on-board machine data to better understand your mining operation. Enhancing productivity through truck and shovel asset performance; from payload balance through controlling truck motions to excavator stability and face diggability via unique analysis techniques; including g-level analysis, specific energy analysis and dynamic spec sheets.

Course Content• What is beyond the stopwatch?

• Benchmarks and standards

• g-level analysis

• body payload balance

• Swell factor, fill factor and loose density

• rack, pitch & roll and fatigue KPIs

• Rope shovel vs. hydraulic excavator performance

• Rack, pitch and roll for excavators and shovels

• Specific power and energy analyses

• Dynamic spec sheets in excavator performance

Beyond tkph (enhancing tire performance)

2 Day Courses

Understanding tires, rims and conducting real time tire performance evaluations. From tire designs to performance limitations to failure modes, tire life is put into context. Tire and rim fatigue and the relationship to running surface performance is explored.

Course Content• Tires – how they work

• Tire failure modes and life expectancy

• Evaluating tire performance

• OEM and mine conventional average tkph

• real time tkph monitoring

• Rim construction and design

• Rim performance

• Haul road housekeeping and rim-tire life

Rock & Roads

2 Day Courses

Understanding rock from exploration through operations to closure. Emphasis on broken rock strength, stability and bearing performance under mining equipment; for roads and rock dumps. Evaluating dig performance in mining faces and GET wear. Rolling resistance and conducting simple, quick and low cost operational field intact and broken rock strength tests. Using test results to improve operational planning and decisions. Over a dozen unique hands-on tests will be experienced.

Course Content• Interpreting core

• Intact versus broken rock density

• Intact versus broken versus rock mass strength

• Measuring rock strength – index and field tests

• Measuring rock strength – easy to do lab tests

• The quickest way to a rock strength relationship

• Measuring broken rock strength

• Hauler rolling resistance

• Excavator dig resistance

• Dump and slope stability

• Cyclic plate load test and ground pressure stiffness

• Designing haul roads and excavator pads

• GET wear prediction

Safe blasting practices (restricted attendance)

2 Day Courses

A course restricted to attendees with letters of approval from recognized (mine operation) management. Attendees can proceed to write their provincial blasting ticket examinations on later achieving 6 months as a blaster’s helper in the field. All aspects of practical safe blasting practice including drilling, explosives, blast design, loading, initiation, plus minimizing ground vibration, airblast and flyrock. The connection from blast to diggability to crusher performance in examined.

Course Content• OH&S rules around safe blasting practice – case scenarios

• Geology considerations

• Blast hole drilling

• Drilling and specific energy to do the job

• Explosives

• Surface and underground blast design

• Fragmentation to excavator and crusher design

• Blasthole loading practices

• Connections and Initiation systems

• Ground vibration

• Airblast and flyrock

• Safety scenarios

E-3 Electrification, Environment & Economics

2 Day Courses

EIAs, mine waste streams and sustainability are examined with the community in mind. Novel relationships between mine, community and government are discussed, as positive leverages to achieve a mine design for community sustainability beyond closure. ARD, water, artisanal mining and social license to operate are case study foci. Landform design for sustainable closure with agro-forestry through eco-tourism options are considered. Emissions reductions through operational actions are highlighted.

Course Content• Electrifying haulage, batteries and charging

• Electrification infrastructure & asset / road performance

• Justifying electrification versus emissions and operating conditions

• Reclamation vs. restoration vs. rehabilitation

• Agroforestry, phytoremediation and phytostabilization

• Eco-tourism

• Opportunities & constraints & Landform design

• Social license to operate

• The role of community in mining operations

• Communities finding closure prosperity in mine waste

• Water issues

• Acid Rock Drainage, heavy metal and cyanide treatment

• Sustainable mining & economics

Mine operation economics and life cycle costing

2 Day Courses

Canadian mining economics and commodity price prediction in a global marketplace are introduced. Capital and operating costs for mining operations are predicted using cost index approaches. Leveraging sustaining capital through early reclamation bond recovery is discussed. A life cycle cost analysis approach is detailed for mining equipment assets, highlighting the net zero cost for adding support assets such as motor graders.

Course Content• Canadian mining economic trends

• Commodity price cyclicity

• Capital cost estimation

• Available capital and operating expense to mine

• Marshall and Swift cost leveraging

• Operating costs

• NPV challenge

• Mining security bonds and bond recovery as sustaining capital

• Life Cycle Cost (LCC) Analysis

• LCC Risk

Improving mine maintenance practice

2 Day Courses

From conventional mine maintenance metrics, through bathtub curves, to the value of the P-F curve in predicting asset maintenance and repair prediction is explained. The JPI novel predictive P-F analysis approach is introduced with examples. TPM, CBM and RCM are discussed in achieving appropriate PM practices. Aspiring to best practice and changing maintenance organization and culture are evaluated with a forward thinking case study. Workload and leveraging autonomous (operations) maintenance are compared to MARC and RAMP contracts.

Course Content• Conventional maintenance metrics (MTBF etc)

• The ‘bathtub’ curve

• P-F curves

• Generating a P-F curve to predict maintenance needs

• Root cause analysis and risk evaluation process

• TPM, RCM and CBM

• A PM standard?

• Moubray’s axioms – a discussion challenge

• Maintenance organization and culture

• Changing culture to a team approach

• An observational approach to maintenance

• What is best practice

• Aspiring to best practice – case study

• Making a change to autonomous maintenance

• Workload

• MARC and RAMP agreements with OEMs and service providers

Enhancing operations – graders and dozers

2 Day Courses

This course is only open to those that have previously attended Rock Performance. Rolling resistance (RR) as indicated by hauler performance is used as a tool to indicate running surface performance. Impact of RR on tkph, emissions and structural fatigue with and without grading is investigated. Grader operational capability and GET wear are analyzed. Dozer operational performance in rip, cut and push (trap) modes as a function of ground/rock behaviour. Dozer blade ad ripper GET wear performance is analyzed.

Course Content• Hauler indicated poor RR conditions

• Evaluation of hauler – ground contact loading by duty cycle

• Cyclic plate load field test to indicate rate of trafficked ground deterioration

• Evaluating road design deterioration

• Impact of grading on RR

• Impact of grading on tkph and tire life

• Impact of grading on hauler structural fatigue

• Impact of grading on hauler emissions

• Grader operational capability

• Grader GET (blade) wear

• Dozer push (trap) capability

• Dozer cut and push capability

• Dozer rip capability and rock fragment size generation

Enhancing operations – truck-shovel, IPCC and dragline

2 Day Courses

This course is only open to those that have previous attended (a) Mining Methods, Modes and Machines, (b) Beyond the Stopwatch and (c) Rock Performance. Performance evaluation techniques are reviewed for major mining operation equipment. Interactions between loading and hauling tools are discussed and analyzed. Ground – equipment interactions are analyzed with detrimental stability issues in mind. Hybrid equipment combinations are considered in generating novel site specific mining methods leveraging productivity and asset life.

Course Content• Evaluate hauler performance

• Evaluate shovel / excavator performance

• Evaluate IPCC performance

• Evaluate dragline performance

• Truck – shovel interactions

• Shovel – IPCC interactions

• Equipment – ground interactions

• Pad, road and highwall stability issues

• Running surface design impact on truck & tire performance

• Hybrid performance enhancing alternatives

Course Request

Contact Us

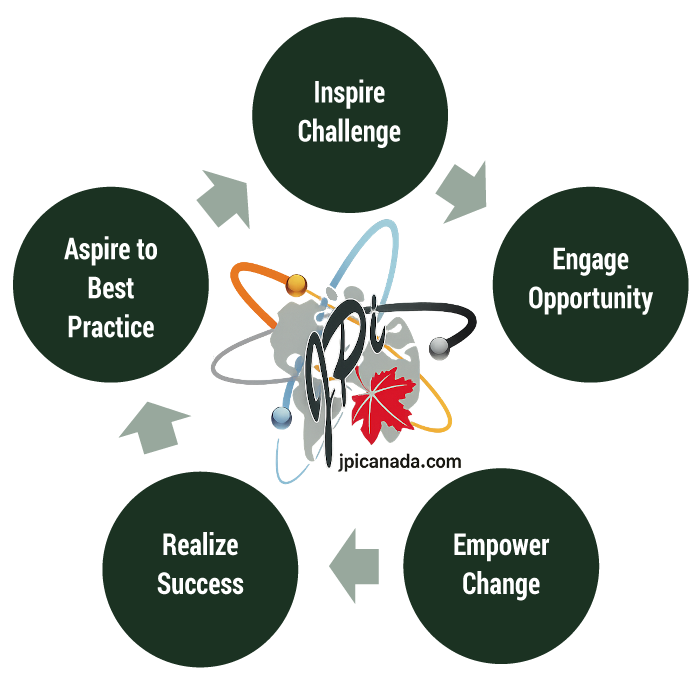

JPI mine equipment is based out of St. Albert, Canada. Contact us to discover what short courses we can offer you today; to allow you to make more informed, immediate and significant cost-effective, sustainable and operational changes.

admin@jpicanada.com